SERVICES

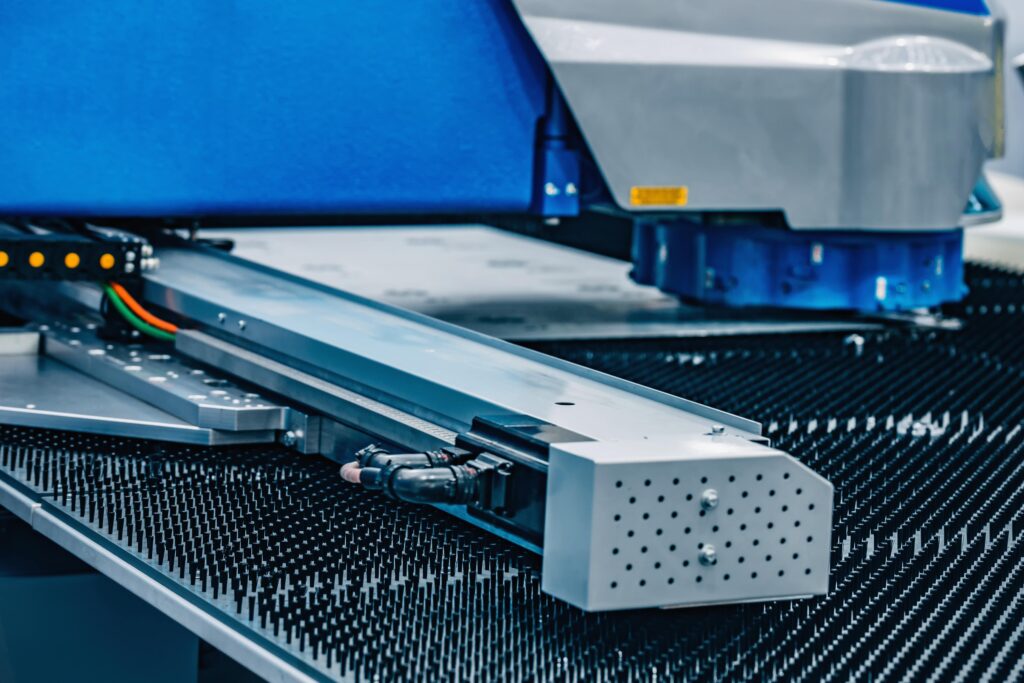

laser Cuting

We can cut up to 4 meters in length . For many thickness of materials the fastest way to cut is laser cutting. We can cut Steel Sheet, Chrome, Brass, Copper, Stainless Steel etc. It uses a laser to cut materials , and is often used for industrial manufacturing applications, but also schools, technology is starting to be used by small businesses and hobbyists. Laser optics directing the work of the most common high power lasers in the sector. laser optics and CNC ( computer numerical control) of the material used directly or the generated laser beam. CNC or pattern G – code will include a motion control system to keep track of the material to be cut on a typical commercial laser to cut materials . The focused laser beam, After leaving aside high quality surface melts , burns , or blown away by evaporation from a material gas jet is directed . Industrial laser cutter is used to cut flat sheet materials as well as structural

Plasma Cutting

Plasma and Oxy-Fuel cutting systems are able to cut Steel up to 200 mm thickness.

We can work in Dual side rack, pinion system AC Servo motor on X axis, and Y axis. Precision Plasma 130/260 Ampere

Standard Marking on Precision Plasma and Automatic torch height control.

Effective cutting without reducing the cutting speed for the vectors which have the same start and end angles (High speed machining )

The ability to go back to any position and resume cutting. Resume feature. Working with standard DIN/ISO G Codes.

Bending

CNC machines are becoming more important these days. Bending machines are more qualified, faster and easy to use. These improvements provide better quality and competition. This is possible with computer controlled machines.

We are using qualified raw materials because of that our finished goods resulted better. Using new technologies and selected raw materials results better finish together. Technology makes most things possible, especially in the steel sector.

Punching

Our Punch Machine offers significantly faster punching speeds than mechanical turrets. The punching head stroke rates of 1200 strokes per minute during punching and 3200 per minute during marking. Also can be formed at punching speed. The machine control adjusts stroke travel speed and position. Simplifies setup of progressive forms, flanges, and embossments. With roller technology are possible not only on straight geometries but also on curved and round areas. This method is of particular interest for sectors such as air conditioning technology. We are here for you today, tomorrow and forever.Through the above article, we can recommend you the latest dresses.Shop dress in a variety of lengths, colors and styles for every occasion from your favorite brands.

Hydraulic Sheet Forming Press

We have more than 40 different design sheets for steel security door skins. We are able to produce more than 1000 Tons per month in this machine. Our machine capacity includes 300 Tons to 5000 Tons. We have different machines for different designs.

Surface Treatment

is the process of applying a protective zinc coating to steel or iron,to prevent rusting. The most common method is hot-dip galvanizing in which parts are submerged in a bath of molten zinc.

Galvanizing

It forms a coating of corrosion-resistant zinc which prevents corrosive substances from reaching the more delicate part of the metal. The zinc serves as a sacrificial anacode so that even if the coating is scratched, the exposed steel will still be protected by the remaining zinc. The zinc protects its base metal by corroding before iron, for better results application of chromates over zinc is also seen as an industrial trend. Hot-dip galvanizing deposits a thick robust layer of zinc iron alloys on the surface of a steel item. In the case of automobile bodies, where additional decorative coatings of paint will be applied, a thinner form of galvanizing is applied by electrogalvanizing.

Painting

On the steel we are able to make a wide range of paintings. Steel production is not finished until you coat it. Therefore we also offer painting. Most of the demanded paintings are Powder Coating Paint, Liquid Paint, Spray Treatment Paint. We kindly accept all kinds of demand from our business partners.

Welding

Akfaport focused on a wide range of metal fabrication services, including welding. Our welders have experience in MIG MAG and arc welding. Akfaport serves multiple industries including machining, automation, wrought Iron, Steel Door, food processing, printing equipment, etc.

Our business is centered on our quality . Our welding services produce the products with highest quality. we fabricate for our customers as to the demand

Saw

Regarding the cutting of our products, we cut all kinds of products in the desired lengths according to the demands of our customers. In many cutting tracks related to steel cutting, we cut the products in the lengths according to the demands of our customers, with our talented and experienced staff.

Finished Goods & Assembled Goods

Akfaport manufactures finished or semi-finished products to meet the needs of its customers in many areas. In our company, which is one of the pioneers in the steel industry, we produce turnkey products with our wide range of capabilities as iron processing.

We produce and deliver complementary steel products to our customers’ production lines at competitive prices.

Our business is centered on our quality . Our welding services produce the products with highest quality. we fabricate for our customers as to the demand